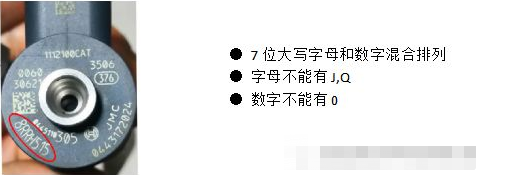

The injector compensation correction code is a series of codes composed of numbers and letters. When the injector is manufactured, it is printed on the engine body as a record of the injection diameter, the size of the gauge hole, the diameter of the solenoid valve and other parameters, the Ecu can read and generate the offset signal, and conduct and control the output parameters of the injector, such as the injection quantity and response time, so as to promote the consistency of the injection parameters and ensure the normal operation of the engine.

With the development of modern production capacity, diesel locomotive is widely used in large-scale warehouse freight transportation and operation activities. We all know that diesel Fuel injection is the core of diesel locomotive operation, it is composed of high-pressure oil pump, high-pressure oil supply pipe, injector and electronic control unit (Ecu) , which puts forward more strict requirements for its accuracy and efficiency in work, and any of these components will cause diesel vehicle failure, affect the progress of transportation, resulting in inevitable economic losses.

Even if some of the original information of the injector such as the gauge hole and the injection diameter change slightly due to wear and tear, it will affect the normal prediction of the ECU and will not be able to accurately control it, thus resulting in abnormal injection volume and abnormal engine, then, it will cause the diesel vehicle shaking, smoke, lack of power and other abnormal driving phenomena.

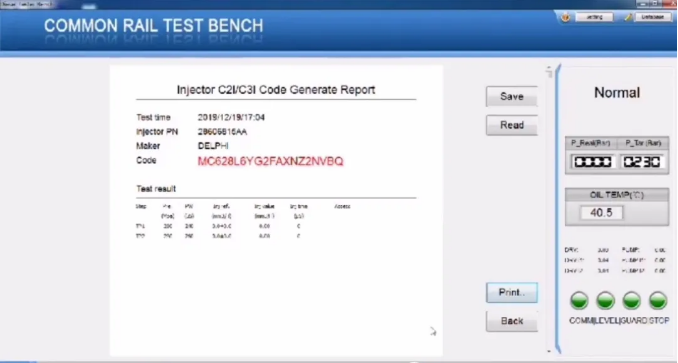

The test-bed with coding function can solve this problem very well. In essence, it works in a simulated engine. The computer acts as an Ecu to obtain the working parameters of the injector under different working conditions, and compares them with the original parameters, and through a certain algorithm, get a series of new compensation code, used to replace the original code to ensure the normal operation of the engine, the normal operation of diesel vehicles, greatly improve the efficiency. Compared with the conventional detection, the new fuel correction code printed by the test-bed with the function of coding can intelligently adjust the fuel injection parameters in the engine, and after loading, the driving power can be felt to increase obviously, be Able to better solve problems such as start-up difficulties, lack of power and so on. Some injectors use only routine testing, and even if you know what the problem is, you still can't find a good solution. This is why the coding function once online can quickly occupy the front end of the market. Such a powerful function, if a large number of introduced to the school pump shop, will be better radiation surrounding, help truck drivers in the driving, timely resolution of functional barriers occurred. Not only improve the ability to solve the problem, but also to a greater extent to increase the economic benefits of the maintenance staff is really a great blessing.

Although the functions are good, the requirements are more stringent, and for the generation of compensation codes, the premise must ensure that the test-bed test accuracy is close to the original equipment, otherwise the compensation codes obtained through inaccurate test values not only can not correct the injector, on the contrary, it may cause greater difficulties in maintenance. The scientific research cost of the test-bed with coding function is also quite huge. The coding function of a mature injector test-bed is worth tens of thousands of RMB. So what kind of test-bed manufacturers have this ability.

Wuxi Chengshunda Automobile Technology Co. , Ltd. (Jingzhenghongye) has long been committed to the research of accurate common rail injector testing equipment. At present, a number of new common rail injector equipment has been put on line, such as JZ-825, JZ-919, JZ-916, etc. , all the details of the process are up to the standard of the original test-bed, after a long time verification, the generated compensation code is close to the original results. After the line has been widely recognized and praised by everyone.